You need a clear strategy to choose a trackless dark ride manufacturer. Start by identifying your project goals and technical needs. Compare manufacturers based on their proven capabilities and ability to deliver ongoing support. A structured, criteria-based approach helps you maximize your return on investment and guest satisfaction. Before you begin, consider your unique vision and future needs. Avoid frequent industry mistakes:

- Neglecting safety standards.

- Ignoring total cost of ownership.

- Overlooking maintenance requirements.

This guide will help you make confident decisions and avoid costly errors.

Key Takeaways

- Define your project goals and technical needs before selecting a manufacturer. This clarity guides your evaluation process.

- Prioritize safety standards and certifications. Ensure the manufacturer meets all relevant safety requirements to protect guests.

- Evaluate the total cost of ownership, not just the initial price. Consider maintenance, upgrades, and operational costs over time.

- Look for a manufacturer with a proven track record in project delivery. Check references and past project success to gauge reliability.

- Assess the scalability of the ride system. Choose a manufacturer that allows for future expansions and upgrades without major disruptions.

- Ensure strong after-sales support is included. Reliable support minimizes downtime and keeps your ride operational.

- Involve all stakeholders early in the process. Aligning expectations helps avoid costly delays and miscommunications.

- Request live demonstrations and site visits. Observing the ride in action provides valuable insights into performance and guest experience.

Why the Right Trackless Dark Ride Manufacturer Matters

Guest Experience & Brand Impact

You want every guest to leave your attraction with a memorable story. The right trackless dark ride manufacturer helps you achieve this by balancing advanced technology with immersive theming. Benoit Cornet, a respected industry expert, explains that technology alone does not guarantee high guest satisfaction. A ride with impressive hardware can still disappoint if it lacks immersion. On the other hand, a less advanced system that delivers a rich, engaging experience often receives better guest reviews. You should look for a partner who understands how to blend technical innovation with storytelling. This approach strengthens your brand and encourages repeat visits.

Safety & Reliability

Safety forms the foundation of any successful attraction. You must choose a trackless dark ride manufacturer that prioritizes robust safety systems and operational reliability. Trackless rides use complex networks of sensors and wireless communication. The most frequently reported safety incidents include:

- System breakdowns due to WiFi connectivity loss.

- Ride shutdowns when a single safety sensor triggers.

- Vehicle misalignment caused by lost communication between units.

You need a manufacturer with proven solutions for these challenges. Reliable safety protocols reduce downtime and protect your reputation. Consistent performance also ensures that guests feel secure throughout their experience.

ROI & Long-Term Value

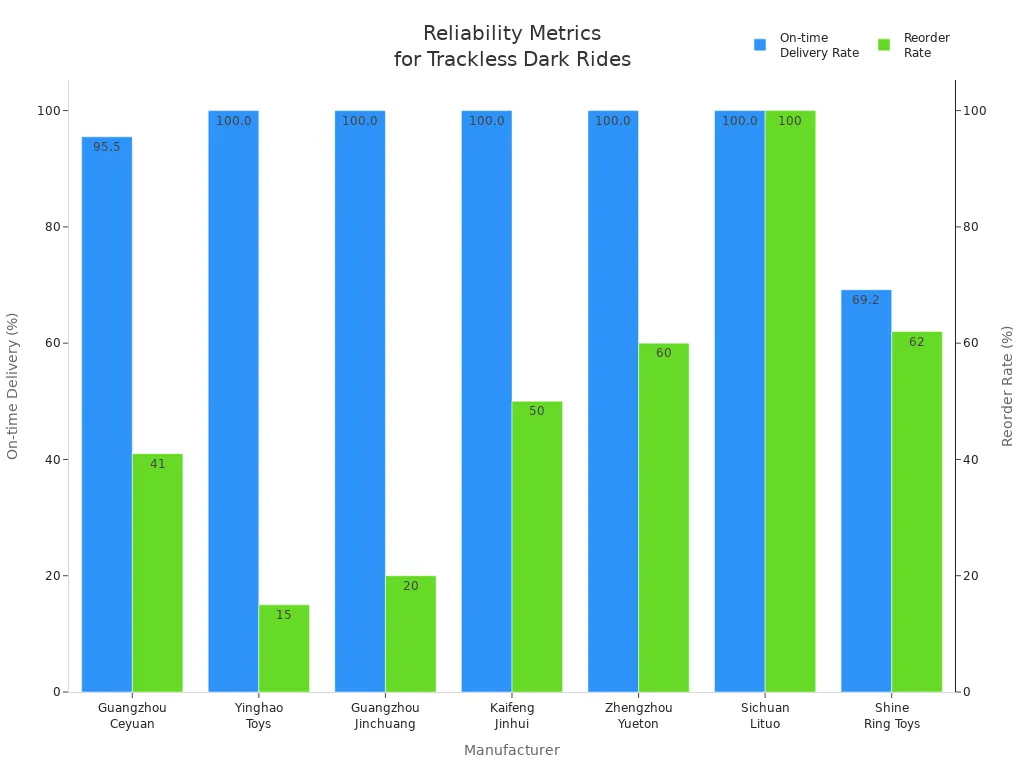

Your investment in a trackless dark ride should deliver value for years. You should evaluate manufacturers based on their reliability, support, and long-term partnership potential. Consider the following comparison of leading companies:

| Company Name | On-time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|

| Guangzhou Ceyuan Electronic Technology | 95.5% | ≤2h | $910,000+ | 41% |

| Yinghao Toys Co., Ltd. | 100.0% | ≤2h | $20,000+ | <15% |

| Guangzhou Jinchuang Health Technology | 100.0% | ≤2h | $18,000+ | 20% |

| Kaifeng Jinhui Amusement Equipment | 100.0% | ≤1h | $47,000+ | 50% |

| Zhengzhou Yueton Amusement Equipment | 100.0% | ≤2h | $710,000+ | 60% |

| Sichuan Lituo Landscape Science & Technology | 100.0% | ≤4h | $130,000+ | 100% |

| Shine Ring Toys Co., Ltd. | 69.2% | ≤7h | $340,000+ | 62% |

You should review on-time delivery rates, response times, and reorder rates when making your decision. A reliable trackless dark ride manufacturer supports your attraction’s uptime and guest satisfaction. This focus on long-term value helps you maximize your return on investment and build lasting success.

Common Selection Pitfalls

You face several risks when selecting a trackless dark ride manufacturer. Many buyers overlook critical factors that can affect the success and longevity of their attraction. Recognizing these pitfalls early helps you make informed decisions and protect your investment.

- Safety Oversights

You may underestimate the importance of advanced safety features. Trackless systems require redundant localization and dynamic obstacle detection to prevent accidents. If you skip a thorough review of these capabilities, you risk frequent breakdowns and guest safety incidents. Always verify that the manufacturer meets industry safety standards and provides robust protocols for emergency situations. - Ignoring Total Cost of Ownership (TCO)

You might focus only on the initial purchase price. Operational costs, maintenance, software upgrades, and spare parts often add up over time. If you neglect these expenses, your budget can spiral out of control. Request a detailed breakdown of lifecycle costs, including maintenance schedules and upgrade paths. This approach ensures you understand the true financial impact of your decision. - Insufficient Evaluation of Navigation Systems

Navigation technology forms the backbone of trackless rides. You need to check safety certifications and maintenance realities. Some buyers accept basic navigation without considering system stability or scalability. This mistake leads to unexpected downtimes and limits future expansion. Ask for case studies and references that demonstrate reliable performance in real-world environments.

Tip:

Create a checklist for your evaluation process. Include safety certifications, maintenance requirements, scalability options, and software upgrade capabilities. This list helps you compare manufacturers objectively and avoid missing key details.

- Lack of Long-Term Support Planning

You may forget to assess after-sales support and training. Without reliable maintenance and documentation, your ride can suffer from extended outages. Confirm that the manufacturer offers ongoing support, clear training materials, and responsive service teams. - Stakeholder Misalignment

You risk project delays if you do not align all stakeholders on requirements and expectations. Hold regular meetings and document decisions to keep everyone informed.

By understanding these pitfalls, you strengthen your evaluation process. You build a foundation for a safe, reliable, and cost-effective trackless dark ride that delivers lasting value.

Defining Project Goals & Requirements

Business Objectives & Audience

You need to start with a clear understanding of your business objectives. This step will guide every decision you make during the selection process. Trackless dark rides serve different purposes depending on your goals and target audience. Review the table below to clarify your main objectives:

| Business Objective | Description |

|---|---|

| Enhancing guest experiences | Investments in trackless dark rides aim to create immersive and interactive experiences for guests. |

| Increasing capacity | The design allows for higher guest throughput, accommodating more visitors per hour. |

| Integrating immersive storytelling | The rides are designed to tell engaging stories, enhancing the overall attraction experience. |

You should identify which objectives matter most for your project. For example, if you want to boost guest satisfaction, focus on immersive storytelling and interactivity. If you need to handle large crowds, prioritize capacity and operational efficiency. Always consider your core audience. Family attractions, thrill seekers, and educational venues each require different ride features and themes.

Tip:

Survey your guests or analyze visitor data to understand what your audience values most. This information will help you communicate your needs to a trackless dark ride manufacturer.

Technical & Operational Needs

You must define your technical and operational requirements early. These needs will shape your project’s complexity and cost. Small-scale rides, such as the Snorri Touren, require careful planning to fit all components into limited spaces. You may need to use detailed 3D models to ensure every element, from decorations to technical systems, fits perfectly. Large-scale projects offer more room for advanced technology and complex systems. You should match your technical requirements to your available space, desired guest experience, and operational goals.

Consider these questions:

- What is the available footprint for your ride?

- How many vehicles do you need to operate at once?

- Do you require advanced navigation or interactive features?

- What level of system scalability do you expect for future expansion?

Clear answers will help you evaluate each trackless dark ride manufacturer’s ability to meet your needs.

Budget & Timeline

You need to set a realistic budget and timeline before you approach manufacturers. Costs can vary widely based on theming, show systems, and interactivity. Review the following budget ranges for mid-sized theme parks:

| Category | Budget Range | Notes |

|---|---|---|

| Dark rides & interactive attractions | $500,000 – $4,000,000+ | Depends on theming, show systems, and media |

| Dark Ride (trackless or tracked) | $500,000 – $10,000,000+ | Theming, show systems and interactivity drive costs upward. |

You should also plan for contingencies and unexpected expenses. Set clear milestones for design, installation, and testing. A well-defined timeline helps you manage expectations and avoid costly delays.

Note:

Always request a detailed cost breakdown from each trackless dark ride manufacturer. This step will help you compare proposals and avoid hidden expenses.

Stakeholder Alignment

You need to align all stakeholders before you select a trackless dark ride manufacturer. Stakeholders include owners, operators, creative teams, technical staff, and sometimes external consultants. Each group brings different priorities and concerns to the table. If you do not secure alignment early, you risk costly delays, scope changes, or even project failure.

Start by identifying every key stakeholder. Use a simple table to clarify roles and responsibilities:

| Stakeholder Group | Primary Concerns | Decision Role |

|---|---|---|

| Owners/Investors | ROI, lifecycle cost, brand value | Final approval |

| Operators | Safety, reliability, maintenance | Daily operations |

| Creative Team | Theming, guest experience | Story/design vision |

| Technical Staff | System stability, upgrades | Technical feasibility |

| Consultants | Compliance, risk management | Advisory |

You should hold a kickoff meeting to gather input from each group. Ask direct questions about their expectations for safety standards, system stability, scalability, and long-term support. Document these requirements in a shared project brief. This document will serve as your reference throughout the selection process.

Tip:

Use a checklist to track stakeholder requirements. Update it after every major meeting or decision.

You must communicate clearly and often. Schedule regular updates and review sessions. Share progress, challenges, and changes in scope. This approach keeps everyone informed and reduces misunderstandings.

Common mistakes include:

- Failing to involve operators early, which leads to overlooked maintenance needs.

- Ignoring creative input, resulting in a ride that lacks guest appeal.

- Overlooking technical staff, which can cause integration issues with existing systems.

You should also set clear decision-making protocols. Define who has final say on budget, safety, and design. This clarity prevents conflicts and last-minute changes.

A real-world example: A European theme park delayed its dark ride launch by six months because technical and creative teams disagreed on vehicle capacity. Early alignment and documented requirements could have prevented this setback.

You build trust and efficiency when you align stakeholders from the start. You also ensure that your trackless dark ride project meets safety, operational, and creative goals—delivering value for years to come.

Technical Capabilities

AGV & Navigation Systems

You need to focus on the core technology that powers trackless dark rides: Automated Guided Vehicles (AGVs) and their navigation systems. These systems determine how smoothly, safely, and flexibly your ride operates. Advanced AGV and navigation technology enables creative layouts, reliable performance, and efficient maintenance.

Recent advancements have transformed what you can achieve with trackless rides. Consider these innovations:

- Omnidirectional movement allows vehicles to travel in any direction, not just forward or backward.

- Guidance wires are no longer necessary, reducing installation complexity and maintenance needs.

- Vehicles can now handle slopes and changes in elevation, expanding your design options.

- Improved speed and acceleration create more dynamic ride experiences.

- Vehicles can make sharp 90° turns without a minimum turn radius, letting you use space more efficiently.

These features let you design immersive, interactive environments that would be impossible with older systems. For a deeper dive into navigation technology, see How Trackless Ride Navigation Works.

When you evaluate a trackless dark ride manufacturer, ask for detailed information about their AGV and navigation systems. Request technical documentation, safety certifications, and case studies. You should also check for:

- Redundant localization systems for safety.

- Dynamic obstacle detection and avoidance.

- Proven stability in real-world installations.

A mature navigation system should operate reliably even in challenging conditions, such as crowded environments or areas with wireless interference. You can read more about AGV safety and reliability in AGV Safety Standards for Amusement Rides.

Tip:

Always request a live demonstration or site visit. Observe how the vehicles handle complex paths, obstacles, and emergency stops.

Common mistakes include overlooking the importance of system updates and software support. Ask about the manufacturer’s upgrade policy and how they handle long-term maintenance. A robust support plan reduces lifecycle costs and ensures your ride stays current with the latest safety and performance standards.

Multi-Vehicle Dispatch

Multi-vehicle dispatch technology controls how many vehicles operate on your ride at once and how they interact. This capability directly affects your ride’s capacity, guest flow, and overall experience.

Modern dispatch systems use advanced algorithms to:

- Minimize passenger wait times.

- Optimize vehicle routes in real time.

- Adapt to changing conditions, such as guest flow or ride interruptions.

You can evaluate a manufacturer’s dispatch system by reviewing their approach to queue management, vehicle grouping, and reporting. The table below summarizes key benefits:

| Benefit | Description |

|---|---|

| Elevate Rider Experience | Guests can request rides or view routes instantly, reducing wait times. |

| Reduce Labor Costs | Automated systems eliminate the need for manual dispatchers. |

| Increase Quality Control | Rider feedback tools provide management with timely insights. |

| Automated Reporting | Access to real-time data without manual spreadsheets. |

A strong dispatch system improves throughput and guest satisfaction. It also supports operational efficiency by reducing labor costs and simplifying quality control. For more details on dispatch technology, see Multi-Vehicle Dispatch in Dark Rides.

Risk Reminder:

If you choose a system with limited dispatch flexibility, you may face bottlenecks during peak hours. Always test the system’s ability to handle high guest volumes and unexpected events.

You should also check for integration with your park’s existing systems. Compatibility with ticketing, show control, and emergency protocols ensures smooth operations.

Terrain Compatibility

Terrain compatibility refers to how well the ride system adapts to different floor layouts, slopes, and surface types. You need to consider this factor early in your planning process. Not all AGV systems can handle uneven surfaces or steep inclines.

Key evaluation points include:

- Maximum slope and incline the vehicles can manage.

- Ability to transition between different floor materials.

- Stability on ramps, curves, and tight corners.

You should request technical specifications and real-world examples from the manufacturer. Ask for references from parks with similar terrain challenges. If possible, visit an installation to see the vehicles in action.

Note:

Poor terrain compatibility can lead to frequent breakdowns, increased maintenance, and guest safety risks. Always verify that the system meets your site’s unique requirements.

You should also consider future expansion. A scalable system allows you to add new scenes or extend the ride path without major modifications. For more on scalability and upgrade paths, see System Scalability in Trackless Rides.

When you assess technical capabilities, use a structured approach. The table below outlines criteria for judging technical maturity:

| Criteria | Description |

|---|---|

| Core Objectives | Define your audience, experience goals, and financial targets. |

| Ride Mechanics | Match system features to your space and guest needs. |

| Vendor Compliance | Review all safety and documentation standards. |

| Operational Readiness | Confirm all systems are ready before accepting the ride. |

By following these steps, you can confidently evaluate the technical capabilities of any trackless dark ride manufacturer. This process ensures you select a partner who delivers safe, reliable, and future-proof attractions.

System Scalability

You need to consider system scalability when you choose a trackless dark ride manufacturer. Scalability determines how well your ride can grow, adapt, or change as your needs evolve. A scalable system lets you expand your attraction, add new scenes, or update technology without starting from scratch.

Trackless dark ride systems offer impressive flexibility. You can design rides that fit small footprints or stretch across large spaces. The vehicles move freely, so you do not have to follow a fixed path. This freedom supports creative storytelling and future upgrades.

“Another interesting piece of trivia is the scope of an attraction like this is virtually unlimited. George Walker told me that this kind of system is only limited by your budget. Meaning, the distance to which these vehicles can be controlled is enormous.”

You should look for these key features when you evaluate scalability:

- Modular hardware that allows you to add vehicles or scenes over time.

- Software that supports easy updates and integration with new show elements.

- Flexible navigation systems that adapt to new layouts or expanded routes.

- Support for future technologies, such as interactive media or advanced effects.

A scalable system gives you options. You can start with a basic ride and add complexity as your budget grows. You can also respond to guest feedback by updating or re-theming sections of the attraction.

Benefits of Scalable Trackless Dark Ride Systems:

- You can support a wide range of ride experiences, from family-friendly adventures to high-thrill journeys.

- You can integrate innovative storytelling that evolves with your brand.

- You can eliminate linear paths, creating dynamic and surprising guest experiences.

- You can increase capacity by adding more vehicles or expanding the route.

- You can adapt to new trends or technologies without major reconstruction.

Here is a quick comparison of scalable versus non-scalable systems:

| Feature | Scalable System | Non-Scalable System |

|---|---|---|

| Expansion Options | Add vehicles/scenes easily | Major redesign required |

| Software Upgrades | Simple, modular updates | Complex, costly changes |

| Creative Flexibility | High—supports new layouts | Limited by fixed paths |

| Lifecycle Cost | Lower over time | Higher due to rebuilds |

| Guest Experience | Evolves with trends | Static, harder to refresh |

You should ask each manufacturer these questions:

- How many vehicles can the system support now and in the future?

- Can you add new scenes or routes without major downtime?

- How does the software handle updates and new features?

- What is the process for integrating new technologies or effects?

- Does the system support remote diagnostics and upgrades?

Tip:

Choose a manufacturer with a proven track record of supporting expansions and upgrades. Ask for case studies or references from parks that have expanded their rides.

Common Mistakes to Avoid:

- Focusing only on current needs and ignoring future growth.

- Selecting a system with rigid hardware or software.

- Overlooking the cost and complexity of future upgrades.

- Failing to plan for new storytelling or interactive elements.

You should also consider the risks of poor scalability. If you choose a system that cannot grow, you may face high costs or operational disruptions when you want to expand. You may also struggle to keep your attraction fresh and competitive.

A scalable trackless dark ride system protects your investment. It gives you the power to adapt, innovate, and delight your guests for years to come.

Evaluating Trackless Dark Ride Manufacturer Experience

You need to assess the real-world experience of any trackless dark ride manufacturer before making your final decision. Experience shapes the reliability, creativity, and long-term value of your attraction. You can use three main criteria: industry reputation and portfolio, project delivery and references, and risk management.

Industry Reputation & Portfolio

You should start by examining the manufacturer’s reputation within the themed entertainment industry. A strong reputation signals consistent quality, safety, and innovation. Look for companies with a diverse portfolio of completed projects. This portfolio should include attractions in museums, family entertainment centers (FECs), indoor parks, and horror-themed venues.

How to Evaluate Reputation and Portfolio:

- Review industry awards and certifications.

- Check for positive mentions in trade publications and professional forums.

- Analyze the variety and complexity of past projects.

- Look for evidence of creative collaboration and technical innovation.

Case Example:

A museum in Europe partnered with a manufacturer known for immersive storytelling and robust AGV technology. The project delivered high guest satisfaction and minimal downtime. You can read more about this in Museum Trackless Dark Ride Use Case.

Portfolio Evaluation Table:

| Project Type | Number Completed | Guest Satisfaction | Safety Record | Creative Integration |

|---|---|---|---|---|

| Museum | 8 | High | Excellent | Strong |

| FEC | 12 | Medium | Good | Moderate |

| Indoor Park | 15 | High | Excellent | Strong |

| Horror Attraction | 5 | High | Good | Unique |

Tip:

Request a detailed project list from each manufacturer. Compare the scope, scale, and guest feedback for similar attractions.

You should also check for signs of system stability and scalability in their portfolio. Manufacturers with repeat clients and successful expansions demonstrate reliability and adaptability.

Project Delivery & References

You need to verify the manufacturer’s ability to deliver projects on time and within budget. Reliable delivery reduces risk and ensures your attraction opens as planned. References from previous clients provide insight into real-world performance.

How to Evaluate Project Delivery:

- Ask for documented timelines and delivery milestones.

- Review case studies for completed projects in FECs, indoor parks, and horror venues.

See FEC Trackless Dark Ride Use Case, Indoor Trackless Dark Ride Use Case, and Horror Trackless Dark Ride Use Case. - Contact past clients for feedback on communication, problem-solving, and after-sales support.

Reference Checklist:

- Did the manufacturer meet the agreed timeline?

- Was the project delivered within budget?

- Did the ride meet safety and operational standards?

- How did the manufacturer handle unexpected challenges?

- What level of support did they provide after installation?

Common Mistakes:

- Relying only on marketing materials without checking real references.

- Ignoring negative feedback or unresolved issues from previous clients.

- Overlooking the importance of after-sales maintenance and software upgrades.

Risk Reminder:

If you skip reference checks, you may face delays, cost overruns, or ongoing maintenance problems.

Project Delivery Comparison Table:

| Manufacturer | Avg. Delivery Time | Budget Accuracy | Client Satisfaction | After-Sales Support |

|---|---|---|---|---|

| Manufacturer A | 8 months | 95% | High | Excellent |

| Manufacturer B | 10 months | 90% | Medium | Good |

| Manufacturer C | 7 months | 98% | High | Excellent |

You should prioritize manufacturers with proven project delivery and strong references. This approach protects your investment and ensures a smooth launch.

Risk Management

You must evaluate how each manufacturer manages risks throughout the project lifecycle. Effective risk management prevents safety incidents, technical failures, and costly delays.

Risk Management Standards:

- Compliance with international safety certifications.

- Robust quality assurance processes.

- Redundant safety systems and regular maintenance protocols.

- Clear documentation for emergency procedures and software upgrades.

How to Assess Risk Management:

- Request safety certification documents and audit reports.

- Review maintenance schedules and upgrade policies.

- Ask for examples of how the manufacturer handled past emergencies or technical issues.

Red Flags to Watch For:

- Lack of safety certifications or incomplete documentation.

- Poor communication during project challenges.

- Limited support for system scalability or upgrades.

- High frequency of breakdowns or unresolved maintenance issues.

Note:

Manufacturers with strong risk management offer long-term maintenance support and flexible upgrade paths. This reduces lifecycle costs and keeps your attraction safe and reliable.

Risk Management Evaluation Table:

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Safety Certifications | Yes | Yes | Yes |

| Maintenance Support | Excellent | Good | Excellent |

| Upgrade Flexibility | High | Medium | High |

| Emergency Response | Fast | Moderate | Fast |

You should select a trackless dark ride manufacturer with a proven record of risk management. This ensures your attraction remains safe, stable, and adaptable for years.

Summary:

By evaluating industry reputation, project delivery, and risk management, you build a foundation for confident decision-making. Use case studies, reference checks, and clear standards to compare manufacturers objectively. This process helps you avoid common mistakes and select a partner who delivers lasting value.

Customization & Design Support

Creative Collaboration

You need a manufacturer who values creative collaboration. This process brings together your vision, technical needs, and guest experience goals. Leading manufacturers use integrated design teams. These teams unite creative, engineering, and operational experts. You get a seamless guest experience when all disciplines work together.

Manufacturers support collaboration in several ways:

| Service Type | Description |

|---|---|

| Integrated Design | Unites creative, technical, and operational teams for a cohesive attraction. |

| Visualization | Provides dynamic visualizations to test and validate design choices before construction. |

| Pre-Programming | Aligns all teams early, ensuring a unified vision and smooth project execution. |

You should ask for regular design reviews and visualization sessions. These meetings help you spot issues early and keep everyone on the same page. Strong collaboration reduces costly changes and ensures your ride matches your brand.

Theming & Interactivity

You want your trackless dark ride to stand out. Modern attractions focus on immersive theming and interactive experiences. You see a growing trend toward rides that blend storytelling with hands-on elements. Popular rides like Pirates of the Caribbean show that guests still love strong narratives. At the same time, new technology allows for more interactive features.

Key trends include:

- Immersive and interactive experiences that engage all senses.

- A balance between narrative-driven and interactive elements.

- Advanced ride systems that support complex theming and guest participation.

- Flexible designs for both original stories and licensed IPs.

- Compact solutions like the Mini™ Dark Ride, which fit small spaces and offer year-round operation.

You should look for manufacturers who offer customizable media, themed scenery, and special effects. Ask how their systems support both traditional and interactive storytelling. Make sure the ride can evolve with new trends and guest expectations.

Tip:

Choose a manufacturer who can adapt theming and interactivity to your audience and space. This flexibility supports long-term success and keeps your attraction fresh.

Prototyping & Testing

You need confidence that your custom ride will perform safely and reliably. Manufacturers should follow a structured prototyping and testing process. This process reduces risks and ensures compliance with safety standards.

Typical steps include:

| Step | Description |

|---|---|

| 1 | Build prototypes or subassemblies for critical systems like couplers, brakes, and restraints. |

| 2 | Perform both static and dynamic testing to check performance and durability. |

| 3 | Involve third-party testing and certification bodies early to meet ASTM F24 and regional rules. |

| 4 | Obtain CE marking and prepare all required technical documentation. |

| 5 | Document all testing to support insurance and reduce commissioning issues. |

You should request detailed test reports and certification documents. Early and thorough testing helps you avoid delays and costly fixes after installation. It also supports long-term maintenance and system upgrades.

Risk Reminder:

Skipping or rushing prototyping and testing can lead to safety issues, higher lifecycle costs, and insurance problems. Always verify the manufacturer’s process and track record.

By focusing on creative collaboration, advanced theming, and rigorous testing, you ensure your trackless dark ride delivers a unique, safe, and lasting guest experience.

Safety, Compliance & Support

Safety Standards & Certifications

You must prioritize safety when selecting a trackless dark ride manufacturer. International standards and certifications protect your guests and your business. These certifications show that a manufacturer follows strict rules for design, construction, and operation.

Here is a table of key certifications you should check:

| Certification | Description |

|---|---|

| CE | European Conformity, indicating compliance with health, safety, and environmental protection standards for products sold within the European Economic Area. |

| UKCA | UK Conformity Assessed, a mark for products sold in Great Britain, ensuring they meet safety standards. |

| SABER | Saudi Arabia's regulatory framework for product safety and compliance. |

| TUV | Technical Inspection Association, certifying products for safety and quality. |

| ASTM | American Society for Testing and Materials, providing standards for various materials and products. |

| EN 13814 | European standard for the safety of amusement rides and amusement devices. |

You should ask each manufacturer for proof of these certifications. Review their technical documentation and audit reports. If a manufacturer cannot provide these, you risk non-compliance, insurance issues, and possible shutdowns.

Tip:

Always verify that certifications are current and cover both hardware and software components.

Maintenance & Upgrades

You need a ride system that stays safe and reliable over time. Maintenance and upgrade support play a key role in long-term performance. A strong maintenance plan reduces downtime and extends the life of your investment.

Look for manufacturers who offer:

- Scheduled maintenance contracts.

- Spare parts supply.

- Warranty services.

- Software upgrade paths.

Ask for a sample maintenance schedule. Review how the manufacturer handles emergency repairs and routine inspections. You should also check if they provide remote diagnostics or predictive maintenance tools. These features help you spot problems early and avoid costly breakdowns.

A common mistake is to focus only on the initial purchase. You must consider the total cost of ownership, including ongoing maintenance and future upgrades. If you ignore these, you may face higher costs and more frequent outages.

Training & Documentation

Proper training and clear documentation keep your ride safe and efficient. You should ensure that operators and maintenance teams receive hands-on training. This training should cover safe operating procedures, emergency protocols, and daily inspection routines.

Key resources you should expect:

- Operator manuals.

- Maintenance guides.

- Training records.

- Emergency procedure documents.

Manufacturers often provide structured training programs for your staff. These programs help you maintain safety standards and reduce human error. You should keep all training records and manuals as part of your technical file. This practice supports compliance and helps with insurance claims.

Risk Reminder:

Skipping training or losing documentation can lead to safety incidents and regulatory fines. Always keep your records up to date and accessible.

By focusing on safety standards, maintenance, and training, you build a foundation for a reliable and compliant trackless dark ride. This approach protects your guests and your business for years to come.

After-Sales Support

You need strong after-sales support to protect your investment and keep your trackless dark ride running smoothly. Even the best-designed systems require ongoing attention. Without reliable support, you risk extended downtime, higher costs, and frustrated guests.

Why After-Sales Support Matters

After your ride opens, you will face routine maintenance, unexpected repairs, and software updates. A manufacturer with robust after-sales support helps you solve problems quickly. This support keeps your attraction safe, stable, and compliant with industry standards.

Key Elements of After-Sales Support

You should look for these essential services:

- 24/7 Technical Assistance: Quick help reduces downtime and keeps your ride operational.

- Remote Diagnostics: Fast troubleshooting identifies issues before they become major problems.

- Spare Parts Availability: Ready access to parts shortens repair times.

- Software Updates: Regular updates improve safety, stability, and guest experience.

- On-Site Support: Skilled technicians can handle complex repairs or upgrades.

Tip:

Ask each manufacturer for a sample support agreement. Review response times, escalation procedures, and included services.

How to Evaluate After-Sales Support

You can use the table below to compare manufacturers:

| Support Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| 24/7 Hotline | ✅ | ✅ | ❌ |

| Remote Diagnostics | ✅ | ❌ | ✅ |

| Spare Parts Stock | ✅ | ✅ | ✅ |

| Software Upgrades | ✅ | ✅ | ❌ |

| On-Site Response Time | <24 hours | <48 hours | <72 hours |

You should contact references to confirm real-world support quality. Ask how quickly the manufacturer responded to issues and whether promised services matched actual performance.

Common Mistakes and Red Flags

Many buyers overlook after-sales support when comparing costs. This mistake can lead to higher lifecycle expenses and more frequent ride interruptions. Watch for these warning signs:

- Vague or limited support agreements

- Slow or inconsistent response times

- Lack of local service partners

- No clear process for software upgrades

Risk Reminder:

Weak after-sales support increases downtime, reduces guest satisfaction, and raises your total cost of ownership.

Case Example

A family entertainment center in Asia experienced repeated vehicle faults. The manufacturer’s 24/7 hotline and remote diagnostics allowed quick fixes, minimizing guest disruption. In contrast, another park faced weeks of downtime due to slow parts delivery and limited technical support.

Best Practices

- Request detailed support documentation before signing a contract.

- Ensure support covers both hardware and software.

- Plan for regular reviews of support performance.

You build long-term success by choosing a manufacturer with proven after-sales support. This decision safeguards your ride’s safety, stability, and value for years to come.

Cost & Value Analysis

Pricing Models & Inclusions

You will encounter different pricing models when you request proposals from a trackless dark ride manufacturer. Some companies offer fixed-price contracts, while others use milestone-based or cost-plus structures. Each model has unique implications for your budget and risk profile.

Common Pricing Models:

| Model | Description | Typical Use Case |

|---|---|---|

| Fixed Price | One total price for the entire project | Well-defined scope |

| Milestone Payments | Payments tied to project stages | Complex, multi-phase projects |

| Cost-Plus | Actual costs plus a set fee or percentage | Projects with many unknowns |

You should always request a detailed list of inclusions. This list must cover vehicles, navigation systems, show control, installation, training, and after-sales support. Some proposals may exclude items like theming, media, or spare parts. These omissions can lead to unexpected costs later.

Tip:

Ask for a side-by-side comparison of inclusions from each manufacturer. This approach helps you identify hidden costs and avoid surprises.

Total Cost of Ownership

You need to look beyond the initial purchase price. The total cost of ownership (TCO) gives you a complete picture of your investment over time. TCO includes all expenses related to installation, operation, and maintenance.

Key TCO Components:

- Installation and commissioning

- Routine and preventive maintenance

- Energy consumption

- Repair frequency and spare parts

- Software upgrades and system updates

- Staff training and documentation

You should focus on optimizing long-term ROI, not just minimizing upfront costs. A lower initial price may hide higher maintenance or energy expenses. For a deeper dive, see the Trackless Dark Ride Cost Analysis Guide.

Risk Reminder:

If you ignore TCO, you may face budget overruns and reduced ride uptime. Always request a multi-year cost projection from each manufacturer.

ROI Considerations

You want your investment to deliver strong returns. ROI analysis helps you measure the value your ride brings over its lifecycle. Consider both direct and indirect benefits.

ROI Evaluation Methods:

- Calculate payback period based on projected attendance and ticket sales.

- Estimate increased guest satisfaction and repeat visitation.

- Factor in operational savings from efficient systems and automation.

- Assess the impact of system stability and scalability on long-term value.

A reliable ride with low downtime and flexible upgrade paths will protect your revenue and brand reputation. For more on ROI strategies, visit the Dark Ride ROI Evaluation Resource.

Common Mistake:

Many buyers focus only on price and overlook long-term value. You should balance cost, quality, and support to maximize ROI.

By analyzing pricing models, TCO, and ROI, you can confidently compare manufacturers and select the best partner for your project.

Avoiding Price-Only Decisions

You may feel tempted to choose a trackless dark ride manufacturer based only on the lowest price. This approach often leads to higher costs, safety risks, and disappointing guest experiences. You need to look beyond the initial quote and consider the full value each manufacturer brings to your project.

Key Factors to Consider Beyond Price:

- Total Cost of Ownership (TCO): The purchase price is only the beginning. You will face ongoing costs for maintenance, spare parts, software licensing, insurance, and even seasonal storage. Some systems may require frequent upgrades or have parts that become obsolete quickly. These hidden expenses can add up and impact your budget over time.

- Safety Compliance: You must ensure the manufacturer meets all relevant safety standards and certifications. This includes international requirements and any state-specific rules. A lower-priced system that lacks proper compliance can expose you to legal risks, insurance problems, and even forced shutdowns.

- Guest Experience Fit: You should match the ride system to your audience’s expectations. Use guest data and feedback to guide your decisions. Do not rely on assumptions. A ride that fails to engage or delight guests will not deliver long-term value, even if it costs less upfront.

Tip:

Always request a detailed breakdown of what is included in the price. Compare proposals side by side to spot missing features or services.

Case Example:

A small park selected the lowest-cost manufacturer for a new dark ride. The initial savings disappeared within the first year due to frequent breakdowns, high maintenance bills, and poor guest reviews. The park later invested in a system with better support and safety features, which improved uptime and guest satisfaction.

Comparison Table: Price-Only vs. Value-Based Decisions

| Decision Approach | Short-Term Cost | Long-Term Cost | Safety Risk | Guest Satisfaction | Upgrade Flexibility |

|---|---|---|---|---|---|

| Price-Only | Low | High | High | Low | Limited |

| Value-Based | Moderate | Lower | Low | High | High |

You should avoid common mistakes such as ignoring lifecycle costs, skipping safety checks, or overlooking guest needs. Focus on long-term value, system stability, and support. This strategy protects your investment and ensures your attraction delivers memorable experiences for years.

Vendor Evaluation Process & Checklist

Research & Shortlisting

You should begin your evaluation by researching potential vendors. Start with industry directories, trade publications, and professional networks. Look for companies with a strong track record in themed entertainment and proven installations. Focus on those who demonstrate expertise in safety, system stability, and scalability.

Create a shortlist using these criteria:

- Compliance with international safety standards

- Portfolio of completed trackless dark ride projects

- Positive client references and case studies

- Evidence of long-term maintenance and software upgrade support

You can use a simple table to compare initial candidates:

| Vendor Name | Safety Certifications | Number of Installations | Maintenance Support | Upgrade Path |

|---|---|---|---|---|

| Vendor A | CE, ASTM | 12 | Yes | Yes |

| Vendor B | EN 13814 | 8 | Yes | Yes |

| Vendor C | CE, TUV | 15 | No | Limited |

Tip:

Eliminate vendors who cannot provide documentation for safety compliance or who lack experience with similar ride types.

RFP & Evaluation Criteria

Once you have a shortlist, prepare a Request for Proposal (RFP). Your RFP should outline your project goals, technical requirements, budget, and timeline. Clear communication helps each trackless dark ride manufacturer tailor their proposal to your needs.

Key evaluation criteria include:

- System stability and proven uptime statistics

- Scalability for future expansion

- Lifecycle cost, including maintenance and upgrades

- Safety features and certifications

- After-sales support and training

You should request detailed responses for each criterion. Ask for technical documentation, sample maintenance schedules, and references from similar projects. Use a scoring system to compare proposals objectively.

| Evaluation Area | Weight (%) | Vendor A | Vendor B | Vendor C |

|---|---|---|---|---|

| Safety & Compliance | 30 | 28 | 25 | 20 |

| System Stability | 25 | 23 | 20 | 18 |

| Scalability | 20 | 18 | 15 | 10 |

| Lifecycle Cost | 15 | 13 | 12 | 8 |

| Support & Training | 10 | 10 | 8 | 5 |

Risk Reminder:

If you skip a structured RFP process, you may overlook hidden costs or critical safety gaps.

Site Visits & Demos

You should always schedule site visits and live demonstrations before making a final decision. Seeing a system in operation gives you valuable insight into real-world performance, guest experience, and maintenance realities.

During your visit, evaluate:

- Ride vehicle movement and navigation accuracy

- Response to emergency stops and obstacle detection

- Integration with show control and themed elements

- Staff feedback on maintenance and support

Prepare a checklist for your visit. Speak directly with operators and technical staff. Ask about downtime, upgrade experiences, and support responsiveness.

Note:

A live demo can reveal issues not visible in proposals or marketing materials. Trust what you see and hear on-site.

You build confidence in your selection process by combining research, structured evaluation, and hands-on observation. This approach helps you choose a partner who meets your safety, operational, and guest experience goals.

Final Negotiation & Contract

You have reached the final stage of your vendor selection process. Now, you need to secure the best terms and protect your investment. Approach negotiation with a clear understanding of your priorities and non-negotiable requirements.

Start by reviewing the proposal details. Confirm that the contract includes all agreed features, services, and support. Pay close attention to these areas:

- Scope of Work: List every deliverable, from vehicles to software and training.

- Project Timeline: Set clear milestones for design, installation, and testing.

- Payment Terms: Link payments to successful completion of project phases.

- Change Management: Define how you will handle scope changes or unexpected issues.

- Warranty and Support: Specify coverage for hardware, software, and spare parts.

- Safety and Compliance: Require proof of certifications and regular audits.

- Maintenance and Upgrades: Include schedules for preventive maintenance and software updates.

Tip:

Involve your legal and technical advisors during contract review. They can help you spot gaps or unclear language.

You should also negotiate escalation procedures for problem resolution. Set expectations for response times and penalties for missed deadlines. Ask for a sample service-level agreement (SLA) to clarify support commitments.

A case example: A park avoided costly delays by insisting on a detailed escalation process and clear upgrade terms in their contract. This foresight protected their schedule and ensured long-term system stability.

Common mistakes include skipping contract reviews or accepting vague terms. Always document every agreement in writing. This practice reduces risk and builds a foundation for a successful partnership.

Decision Checklist

You need a structured checklist to guide your final decision. Use this tool to compare vendors objectively and ensure you cover every critical area.

| Evaluation Area | Criteria Met? (✔/✘) | Notes/Comments |

|---|---|---|

| Navigation Technology | AGV maturity, safety features | |

| Multi-Vehicle Dispatch | Capacity, real-time control | |

| Terrain Compatibility | Handles slopes, tight spaces | |

| System Scalability | Modular, supports upgrades | |

| Portfolio & References | Similar projects, client feedback | |

| Creative Collaboration | Theming, interactivity support | |

| Prototyping & Testing | Certification, test reports | |

| Safety Standards | CE, ASTM, EN 13814, etc. | |

| Maintenance & Upgrades | Schedule, remote diagnostics | |

| Training & Documentation | Manuals, operator training | |

| After-Sales Support | 24/7 hotline, spare parts | |

| Cost Structure & TCO | All-inclusive, lifecycle cost | |

| Contract Clarity | SLA, escalation, warranties |

Note:

Review this checklist with your project team. Mark each area as complete before you sign any contract.

You can add custom criteria based on your unique needs. This checklist helps you stay organized, avoid common mistakes, and select a trackless dark ride manufacturer with confidence.

Conclusion

You can select the right trackless dark ride manufacturer by following a structured, criteria-driven process. Review your goals, technical needs, and long-term support requirements. Use the checklist to guide your evaluation and avoid common mistakes.

For complex projects, consider reaching out for expert advice or a tailored consultation.

If you want to discuss your project or need a custom solution, you can contact our team for professional support.

FAQ

What is a trackless dark ride?

A trackless dark ride uses automated guided vehicles (AGVs) that move without fixed tracks. You gain flexible layouts, creative storytelling, and easier future upgrades. This system supports immersive experiences and adapts to many attraction types.

How do I compare different manufacturers?

You should review safety certifications, system stability, scalability, and after-sales support. Use a checklist to compare technical features, maintenance plans, and references. Request live demos and visit existing installations for real-world insights.

Why does safety certification matter?

Safety certification ensures your ride meets international standards. You protect guests, reduce legal risks, and support insurance claims. Always verify that the manufacturer provides current documentation for both hardware and software components.

What ongoing maintenance will I need?

You must schedule regular inspections, software updates, and preventive maintenance. Reliable manufacturers offer clear maintenance plans, spare parts supply, and remote diagnostics. This support reduces downtime and extends your ride’s lifespan.

Can I upgrade or expand my ride in the future?

Yes. Scalable systems let you add vehicles, scenes, or interactive features. You should confirm that the manufacturer supports modular hardware and software upgrades. This flexibility protects your investment and keeps your attraction competitive.

How do I avoid hidden costs?

Request a detailed cost breakdown. Review total cost of ownership, including installation, maintenance, spare parts, and software updates. Compare proposals side by side to spot missing items or exclusions.

What should I ask during a site visit?

You should observe vehicle movement, emergency stops, and integration with themed elements. Speak with operators about downtime, maintenance, and support. Use a checklist to ensure you cover all technical and operational questions.

How important is after-sales support?

After-sales support keeps your ride safe, reliable, and up to date. You need quick technical assistance, spare parts, and regular software updates. Strong support reduces downtime and protects your long-term investment.